Why do (American) plugs have holes?

American-style electrical plugs are special in that the prongs “always” have little holes in them:

The question that’s never been answered is why. There have been attempts at answers (and some have some good research). This post is going to evolve over time: my goal is to find as many images of plugs as possible, organized by date.

The timeline seems to be: 1906: Hubbell made an early form of electric plug+socket 1913..1915: there are a bunch of different plugs 1916:NELA starts to try to standardize 1921:each company still makes their original plug and the new standard plug. 1922: standardization is complete.

More updates -- 1913 Lighting Journal has multiple plug types, and the June 1916 Lighting Journal has two interesting articles: one about the attempt to create a single plug standard.

Another update: Hubbell has a modern looking plug in the January 1916 Electrical Age.

Update: the funny-looking Hubbell Attachment Plug is listed in the 1906 Hubbell catalog! (page 36)

1906 Hubbell Catalog

The 1906 Hubbell Catalog, page 34, includes the somewhat oddly shaped Hubbell Attachment Plug. The plug is a user-applied thing: they rewire their device to use the plug, and then screw the socket into a standard Edison-type (or T.H type) screw base.

It's claimed to have been patented August 16, 1892 and also on November 8, 1904.

They call the top thing the "cap" or "plug cap" and the unit as a whole a "plug"

Note that the image does no include any holes in the blades.

1913 Electrical Record, February

This Cutler-Hammer ad shows that a variety of interchangeable sockets for their "double lug" plug. Note that the plug has either dimples or holes.

More Hubble! National Electrical Contractor, November 1914!

Electrical Record, May 1916

Interim Report (1920-ish?)

1915 Gernsback Electrical Experimenter

There’s nothing quite like the 1910’s era electrical magazine. Among the puff pieces are popular accounts of up-to-date science, alongside ads for cheap pistols, motorcycles, and electrical surplus equipment.

World War I had already started by 1915, but America hadn’t yet joined. It surprised me how many German articles are included, including this little piece (page 47 of the June edition) on a novelty cigar lighter:

Unfortunately, the shape of plugs is entirely unremarked. The only plug shown in the entire years set is this bad image of what appears to be a battery charging that’s “plugged” into a ceiling lamp (back cover of the July and other months).

This is a really common setup: almost all picture of things plugged in are plugged into a screw-type light fixture. Here’s a phonograph that can be “plugged in” via a screw-plug: (September 1915, page 186)

Often cartoons show the latest devices the most clearly. This one, from the July 1915 issue, page 117, manages to show an enormous amount of detail without a single plug anywhere (everything is wired directly to a panel which includes some frightening and non-OSHA-compliant switches).

(The July 1915 issue of Electrical Experimenter included reviews of scientific movies, including ‘The Exploits of Elaine’ which I had only read in book form).

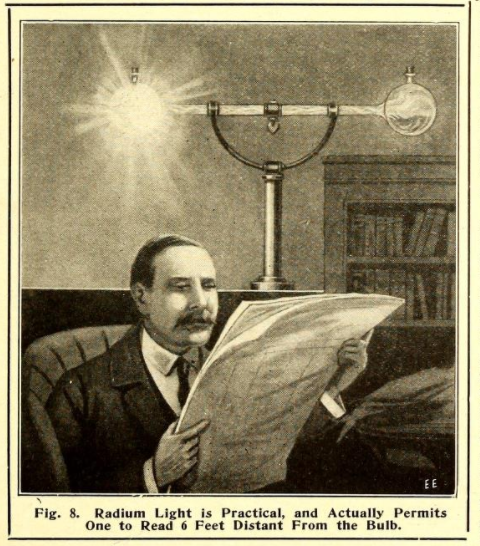

In the terrifying department: a lamp doesn’t need a plug if it’s violently radioactive! (September 1915, page 181)

A very unsatisfying picture of plugged-in equipment at a dentists office in the November 1915 Electrical Experimenter, page 332. The nurse on the left is controlling an electrical respirator; that respirator is plugged into a wall socket. Not shown, of course, is what the plug looks like.

In the same issue: Lionel trains advertises this transformer for their toy trains. Note that it has the old-fashioned screw ‘plug’

1916 Electrical Age (January)

1916 Electrical Age, February

1916 Gernsback Electrical Experimenter

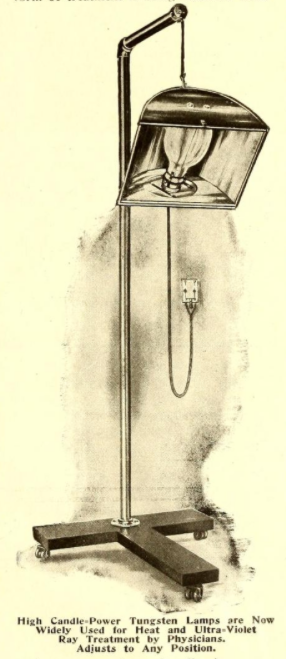

This is almost a plug, but it’s not. It’s a picture of a high-intensity lamp from the February 1916 edition, page 553. What looks like a plug is actually the lamp directly wired to an incredibly dangerous knife switch. As a young’un, I had always assumed that knife switches were used when dealing with lots of current; I was surprised when I started to read the specs and discovered that knife switches are simultaneously dangerous, expensive, and have low current ratings.

I think this is also not a plug (March 1916, page 620)

1916 Electrical Age

1920 Patent 1341468

This 1920 patent shows the little holes in the plug.

1922 NELA bulletin page volume 9 Jan page 23 of 626

Hot darn! The 1922 NELA bulletin has this report from the Wiring Commitee. It seems that by 1922 the plugs were fully standardized:

The standardization of attachment plugs and recepticals having been completed the Committee has been working on advertising this fact.

The Committee is working on standardizing medium size plugs and recepticals for large heater ranges, small motors, etc.

Also on the standardization of the appliance plug, where the cord connects to the flat-iron or other device.

Entry: Catalog Record: Bulletin | HathiTrust Digital Library

The Non-Standard Plugs

Lots of companies sold plugs that aren't the standard plugs. Here's a short list of companies and their plugs.

Arrow standard plugs and sockets

From the National Electrical Contractor, volume 16, February 1917, page 2.

The Arrow company seems to make three kinds of plugs, all with standard prongs:

They have a line of sockets as well (13 pictured in the ad); all seem to have openings for both standard and Hubbell-type inline plugs.

From the Electrical Record, October 1917, page 48, we get this nice cutaway view

Bryant

From Electrical Contractor-Dealer Vol 17, no 9, June 1917.

Bryant had a line of compatible plugs. They have both the horrible half-dome type plug and some more ergonomic plugs.

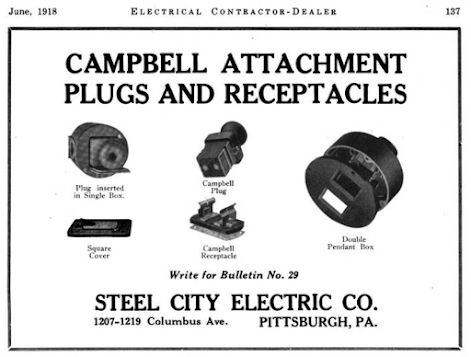

Campbell Attachment Plugs

Campbell Attachment plugs and receptacles (Steel City Electric) from Electrical Contractor-Dealer, June, 1918 page 137

Steel City Electric 1207-129 Columbus Ave, Pittsburgh, PA

Chelten Electric

A pox on all badly-lit and unclear illustrations. This is a socket from the Chelton Electric company, Philadelphia; it's a small ad showing a push-button light switch and this socket. But what kind of socket is it? A standard one, or non-standard?

From the National Electric Contractor, volume 16, November 1916, page 20.

Cutler-Hammer Standard No. 7700

From the Electrical Record, volume 19, May, 1916.

Several electrical manufacturers have agreed on the making of standard plugs and receptacles, the caps and bodies of the various makes of which can be interchanged. This is proving beneficial and convenient both to those in the electrical industry and to the plug. The C-H No. 7700 is the "Standard" type separable plug made the Cutler-Hammer Mfg. Co, of Milwaukee, Wis. This is an all-composition plug, small in size, but having a rating of 660 watts, 250 volts. The accompanying illustration is approximately fully size. The knurled cap does not wear shiny when use, nor show the results of scratches. On the contrary, the makers claim that the appearance of the knurled cap improves with use. The contact blades are firmly riveted to the cap and held in perfect alignment. No screws whatever are used except for those provided for securing the cord terminals. The live parts are concealed.

G-E Standard Separable attaching plugs and sockets

The February 1917 National Electrical Contractor (volume 16, number 4) has several new-to-the-magazine ads. On page 44 is a big G-E (General Electric Company) ad with a set of 3 (or 4) plugs ana 6 sockets. Each socket seems to allow for standard or Hubbell type plugs (but separate, not in a T form). Each plug has a single hole; the other prong does not have a hole.

Hart and Hegeman

A 100% non-compatible plug, sold with the idea that most of the prongs are non-metallic and are less likely to short-circuit. They even have a picture of using a plug through a carpet (they claim that for most rugs the weave an be pushed aside enough to fit a plug).

From From Electrical Contractor-Dealer, Vol 17 number 12, October June, 1918 page 55

Details are from the National Electrical Contractor, volume 7 number 1, November 1907, page 2

The "plug through the rug" picture

They also have an ad in the March 1917 issues, page 119, with a better view of the plug.

"The simple, dignified lines and rich finish of a "Diamond H" Receptacle appeal to the most fastidious task. Nothing cheap-looking here -- nothing conspicuous -- but a sturdy simplicity that suggests sound reliability and real service. And "Diamond H" appearances are never deceitful. There are cheaper receptacles made. We could cheapen "Diamond H" Receptacles if we wished. But-we are possessed of an ideal, viz., to make every "Diamond H" product a standard of quality, not of price.

Then in the November 1907 issue I saw this full explanation and diagram.3

Hubbell Interchangeable Cap and Plug

Jiffy Attachment plug

Here's a picture of a plug with absolutely nothing showing of what the actual plug looks like! Made by (or at least sold by) the Best Electric Company, Pittsburgh, PA.

Their claim is "You can wire TWO "Jiffy's" in the time of ONE ordinary plug. "Jiffy" means efficiency--time-saving, money-saving Efficiency. And it is practically indestructible.

From National Electrical Contractor, vol 16, December 1916, page 133.

And they have a line of them walking along :-)

Lockfast Attachment plug

Made by the yost Electric Mfg Co, Toledo, Ohio. Note that they hardly have a thread on the plug, so it can be screwed in more quickly.

From the May 1916 Electrical Record, page 155.

MESCO (Manhattan Electrical Supply) plug

From National Electrical Contractors, 1918, volume 17, number 7, page 138

MESCO is the Manhattan Electrical Supply Company (17 Park Place, NY)

They have a similar ad in the October 1914 (volume 13, number 12), page 123, but with a small paragraph of text describing the plug.

A Small Separable plug made of black molded material under great pressure. The smoothly finished surface has the appearance of hard rubber. It is extremely tough, will stand hard usage, and is one of the smallest, neatest and most substantial plugs made.

The terminal contacts in the base of the plug are arranged so that it is impossible to short circuit the plug. The cap terminal contacts are of heavy brass, and when inserted into the plug form a strong rubbing contact. Ample space is provided in the cap to knot the cord securely.

From the November? 1913 (volume 13, number 1) National Electrical Contractor, page 98, they also sold this odd-looking plug

Tregoning Plugs

From the 1913 National Electrical Contractor, page 94, is a small add for a non-standard plug

Trumbull Electric Mfg Company

The Trumbell Electric Mfg. Company, Plainville, Conn.

In the April 1917 (vol 16) National Electrical Contractor, page 173, is a notice that the Trumbull company had a new line of standard sockets (but maybe not plugs?)

The Trumbull Electric Manufacturing Company have recently brought upon the market their Side Outlet Current Tap and "Standard" Flush Receptacle, both of which are pictured herewith.

The base and caps are interchangeable with similar products manufactured by Bryant, General Electric, Paiste, Cutler-Hammer, etc. and are included in the so-called "Standard" devices.

From the 1916 Electrical Record, April 1913, page 22

From an ad in the May 1916 Electrical Record, page 208, we learn that the standard attachment plug is catalog 792 for the complete plug and 793 for the "body" only, and that a seven pound pull will separate the cap from the base.

From the 1914 Electrical Record, November 1913

Unilet from the Appleton company

I'm not quite sure what's going on with this socket -- there's a T type socket, but is that a set of crescent-shaped slots, too? And what plug is being shown?

The company is the Appleton Electric Company, 218-230 North Jeffereson St, Chicago

The first is is from the National Electric Contractor, volume 16, November 1916, page 20

The next set are from the January 1917 issue, volume 16 number 3, page 19